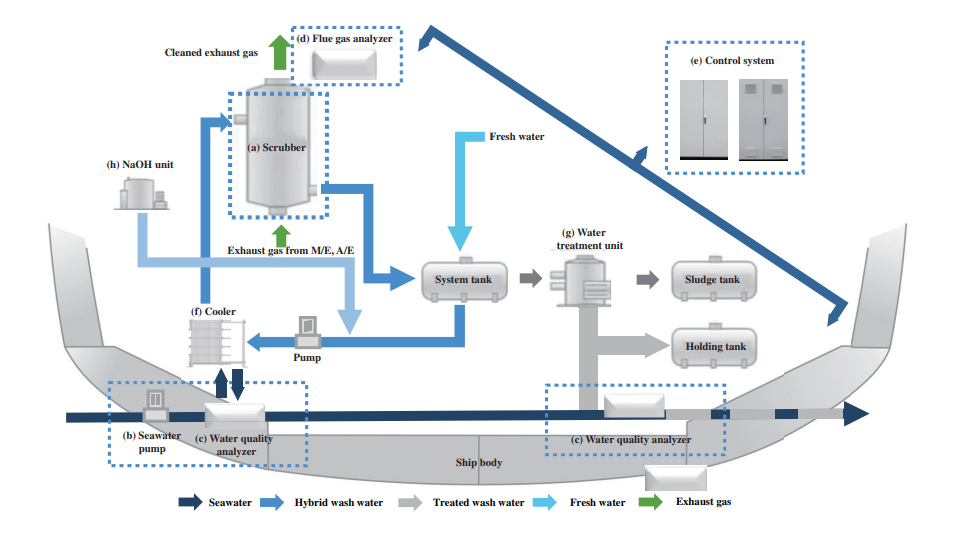

Our marine exhaust gas cleaning solution aims to reduce sulfur emissions from ships and mainly include ship exhaust gas cleaning systems and the spare parts of the products in the system which we mainly provide to our customers of the systems occasionally. Our marine exhaust gas cleaning solution accounted for the majority of our revenue, and represented 78.7%, 64.7%, 66.8% and 59.8% of our revenue for 2021, 2022 and 2023, and the four months ended April 30, 2024, respectively. Our ship exhaust gas cleaning systems have undergone four generations of upgrades to meet customer needs and are characterized by stability, reliability, low energy consumption, and high efficiency in desulfurization reactions. Furthermore, the core component of our ship exhaust gas cleaning systems, the scrubber, features a lightweight design which reduces the power consumption of the ship. In addition, when we design ship exhaust gas cleaning systems, we customize the products by taking into account each ship’s operation patterns to make our systems more energy efficient.

Our ship exhaust gas cleaning systems have two types: open-loop and hybrid, which target customers with different preferences of ship service patterns while ensuring that the sulfur content of the flue gas emissions meets the standards set by the International Convention for the Prevention of Pollution from Ships (“MARPOL”).

Ship exhaust gas cleaning system (open-loop type)

The main product of our marine exhaust gas cleaning solution is the ship exhaust gas cleaning system (open-loop type), which primarily uses seawater as a medium. Seawater is used as an absorbent to neutralize the sulfides present in the flue gas. After the desulfurization treatment, the flue gas is released into the atmosphere, and the seawater, which has reacted with the sulfides, is discharged whenthe ship operates in the open sea during navigation. The open-loop type offers a cost-effective solution due to requiring fewer devices for installation and, subsequently, less device maintenance compared to the hybrid type system.

Ship exhaust gas cleaning system (hybrid type)