--ContiOceanGroup successfully completed its first remote survey of ContiN2G productsduring COVID-19

SinceMarch, due to the COVID-19 in Shanghai,major enterprises have facedincreasingly severe challenges.During the epidemic, the FAT of many productswas faced with a series of difficulties.For example, the surveyor can notarrive at the scene, the technical team can not enter the factory guidance andso on.However, some products are just due to be delivered during the COVID-19and when the COVID-19 will turn around is unpredictable; Product FAT is animportant part of product delivery. The final delivery can be realized onlyafter the inspection of the surveyor is completed .The delivery date ofproducts to be inspected has become one of the major challenges faced byenterprises.

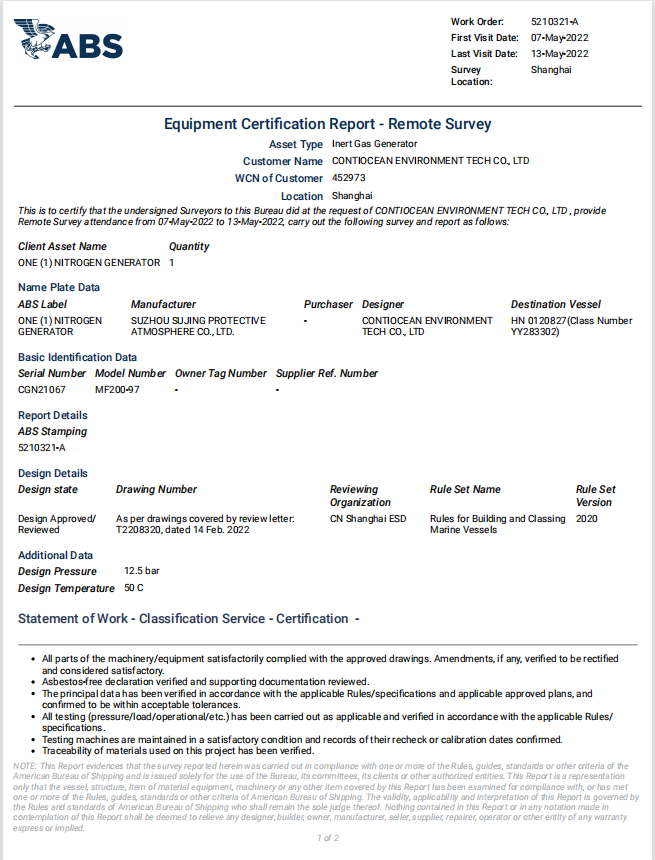

During theCOVID-19, the nitrogen system of 4 vessels signed by ContiOcean Group is duefor delivery. Only after the nitrogen system is in the warehouse can the maindeck of the ship be sealed. If the product cannot be delivered on time, theproduction schedule of the shipyard will be greatly affected. Therefore, inorder to ensure the timely delivery of products, ContiOcean Group actively tookmeasures to complete the FAT survey of ContiN2G products (nitrogen generator)by means of remote survey after full communication with the ship owner,shipyard and ABS (American Bureau of Shipping), and finally completed theremote survey successfully on May 13!

Remote surveyis an inspection method which can share the hole process of FAT with all participants in real time by online meeting,so as to complete the product acceptance work; Compared with the normal FAT,remote survey requires more preparation and stricter requirements forregulations. To this, in the inspection preparation period, ContiOcean Groupfully listened to the opinions of all parties and combined with the matureexperience of many products delivered in the past, preliminary drew up theoverall program of remote survey. Subsequently, ContiOcean R&D personnel oand ABS had an in-depth exchange on the ITP and Remote survey procedure, toensure each step of the remote surveymeet the regulations; After all the technical documents were prepared,ContiOcean Group combined the FAT process with practice and carried out a completeequipment FAT process in the workshop, which ensured that the formal FAT couldbe carried out safely and smoothly.

Afterconducting remote inspection meeting with all parties, remote survey officiallyopened the curtain. The FAT, which included four nitrogen generators, waslive-streamed and recorded by Teams and took photos and uploaded to places withspecial needs. It is completed by ContiOcean professional technical team,including: safety supervisor, inspection supervisor, field operator and recorder.The FAT has carried out the equipment size and appearance inspection, pipelinepressure test, alarm function test and the machine start and stop test.Finally, FAT was divided into two days, and all the inspection contents of foursets of nitrogen equipment were successfully completed.